At Newlife, aluminium extrusion is more than just a service—it’s our specialty and the foundation of our expertise. We are dedicated to continually enhancing our state-of-the-art extrusion presses and auxiliary equipment, ensuring our ability to meet the unique profile needs of our valued clients across various industries.

As the premier aluminium profile supplier in Malaysia, Newlife is committed to delivering excellence and exceeding expectations. Choosing to partner with us means accessing the full potential of aluminium extrusion for your projects.

Contact us today to explore the exceptional possibilities of aluminium extrusion profiles in Malaysia and take your projects to the next level.

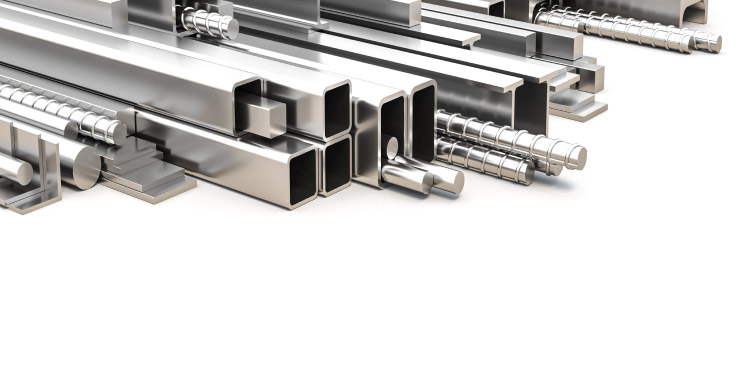

Aluminum extrusion is a process that shapes aluminum by heating it and forcing it through a die with a specific cross-sectional profile. This technique allows for the creation of intricate designs and forms, resulting in lightweight, strong, and durable aluminum parts used in various industries like automotive, construction, and aerospace.

Precision cutting involves the use of advanced machinery to cut materials with exacting accuracy. This process is crucial for ensuring that parts and components meet stringent specifications, often used in manufacturing settings where precise dimensions are critical for assembly and functionality.

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited for anodizing, although other nonferrous metals can also be anodized. The resulting finish can come in various colors and provides a surface that resists further corrosion, enhances aesthetic appeal, and extends the life of the product.

Powder coating is a finishing technique where a dry powder paint is applied to a metal surface, and then heated in an oven to form a tough, wear-resistant layer. This coating is thicker and more robust than conventional liquid paints, providing superior durability, resistance to chipping, fading, and scratching. It is commonly used for outdoor furniture, automotive parts, and appliances for its protective and decorative properties.

Wood grain finishing is a technique used to give metal surfaces a natural wood appearance. This is typically achieved through sublimation, where a wood grain pattern is transferred onto the powder-coated surface of a metal. It combines the aesthetic appeal of wood with the durability and strength of metal, making it popular in applications such as architectural detailing and furniture.